- All Pest & Disease Control

- Actinovate

- ARBORJet

- Big Time Hydroponics

- Bio Green Clean

- BioCare

- Bonide

- Doktor Doom

- Espoma

- FoxFarm

- General Hydroponics

- Green Cleaner

- GreenCure

- Havahart

- Hydro-Organics

- Leaf Shine

- Messinas

- Microbe Life

- Molexit

- Monterey

- MosquitoDunks

- NimBiosys

- Orange Guard

- Orcon

- Organocide

- Physan

- ProControl

- ProKure

- PyGanic

- Quick Kill

- Safer

- Safer Gro

- ScareCrow

- Seabright

- Serenade

- Silva

- SNS

- St. Gabriel Organics

- Weed Prevention Plus

- X-Clude

- Xtreme Gardening

Green Rooster Mono Tub - Mushroom Growing Kit

Green Rooster

MSRP:

Now:

$200.00

(You save

)

- Width:

- 23.00 (in)

- Height:

- 13.00 (in)

- Depth:

- 15.00 (in)

-

Green Rooster

Green Rooster Dub Tub - Mushroom Fruiting Kit

MSRP:Now: $100.00

Green Rooster

Green Rooster Mushroom Spawn Bag

MSRP:Now: $22.95

Green Rooster

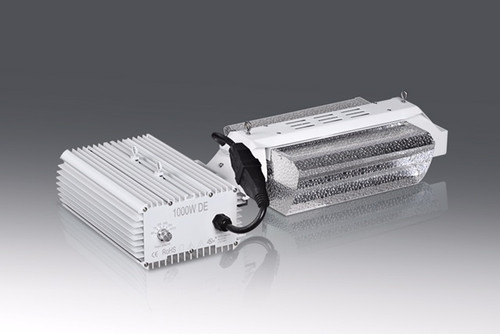

Green Rooster DE 1000

MSRP:Now: $374.93